Sustainability

Developing Eco-Products

Mitsuboshi Belting promotes the production of products that contribute to the reduction of environmental burdens such as energy saving and waste reduction.

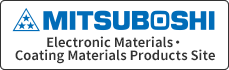

Automobile and Motorcycle Transmission Belts and Related Products

Low Friction Loss Belts

The Japanese automobile industry is intensifying competition for fuel efficiency. To meet that need, we have succeeded in developing a low friction loss belt for auxiliary drive systems. By suppressing the internal heat generation of the belt rib part, we succeeded in reducing the friction loss due to bending and deformation of the belt and improving the transmission efficiency of the belt. As an epoch-making product that achieves low fuel consumption with a single accessory belt among the approximately 30,000 automobile parts, and also has functions such as sound resistance and wear resistance, it has been released to automobile manufacturers. The adoption is widespread.

Energy saving belt e-POWER®

The e-POWER® series is an environment-friendly belt with a special shape (notch, cog, double cog) that reduces bending stress, which is the largest cause of power loss, and enhances energy-saving effects. Since a dedicated pulley is not required, only the belt needs to be replaced, and the power saving effect is improved in the equipment of factories, hospitals, commercial / office buildings, industrial machinery, etc.

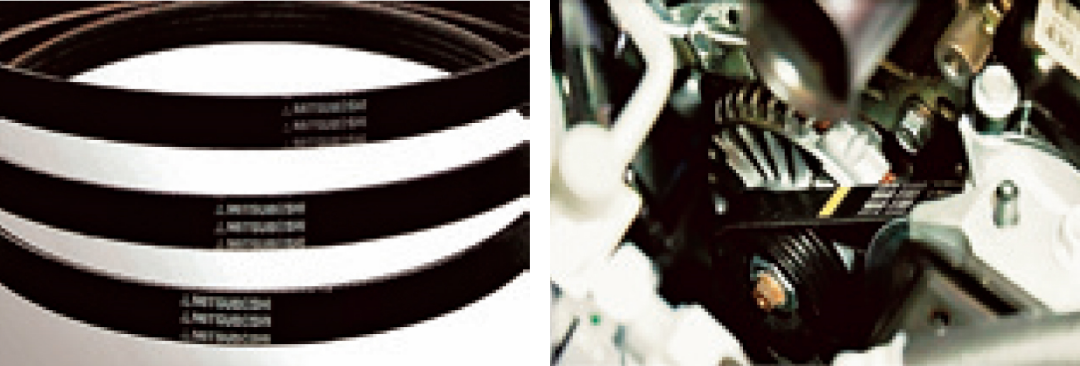

Resin material for cutting Cast-Nylon Series

Cast nylon improves the characteristics of nylon by polymerizing and molding nylon monomer, which is the main raw material, in a mold, and has excellent dimensional stability with little residual strain. The cast nylon series, which is often used for industrial parts such as gears and conveyor rollers, has excellent rigidity, so replacing metal with cast nylon leads to weight reduction of parts and contributes to energy saving.

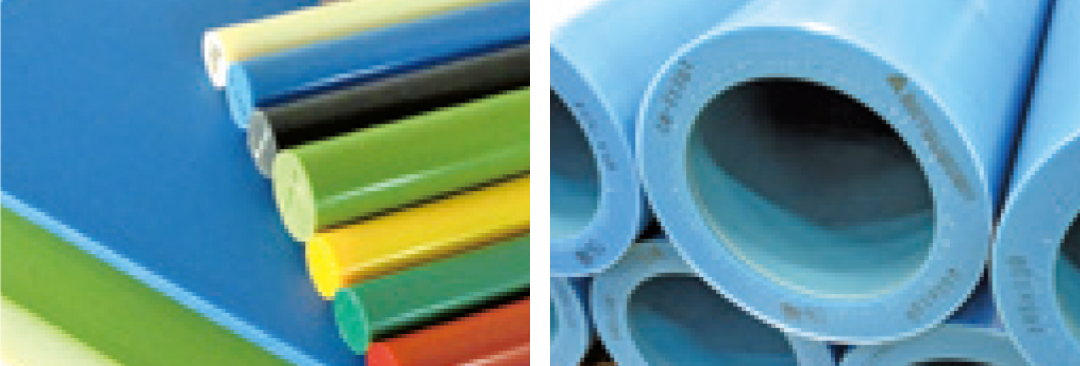

Free span ® belt for wind power generators

It is used to adjust the pitch of blades for wind power generators, which are becoming more and more recognized as renewable energy that does not emit greenhouse gases that cause global warming.

Exposed heat insulation waterproof method Neo hard foam waterproof method

With the tightening of energy-saving standards for buildings, the demand for heat insulation performance for rooftop waterproofing materials is increasing. The neo-hard foam waterproofing method is a high-performance exposed heat insulating sheet waterproofing method that combines hard urethane foam with excellent heat insulating performance and glue-added sulfurized rubber sheet. Since it is an adhesive method, it does not generate noise or vibration compared to the mechanical fixing method. By combining with high solar reflection paint, it demonstrates high energy saving function and reduces air conditioning cost.

Silver nanoparticle paste pigment for mirror decoration

We have developed a paste pigment for mirror decoration of metallic paints and inks as a new application utilizing silver nanoparticles. By adopting a new manufacturing method, silver nanoparticles have succeeded in significantly reducing volatile organic compound (VOC) emissions during manufacturing compared to conventional manufacturing methods.

In addition, since it is most suitable as a pigment for mirror surface decoration in painting and various printing methods, it can be replaced with plating and thin-film deposition methods that are concerned about environmental load, and it is an environmentally friendly type that can contribute to reducing the environmental load on the customer side. It is a product.

Substrate: Glass container / Technique: Spray painting

Base material: Resin plate / Technique: Screen printing

_eng.png)